ELDRUT Sp. z o.o. Przebendów 42A, 39-308 Wadowice Górne

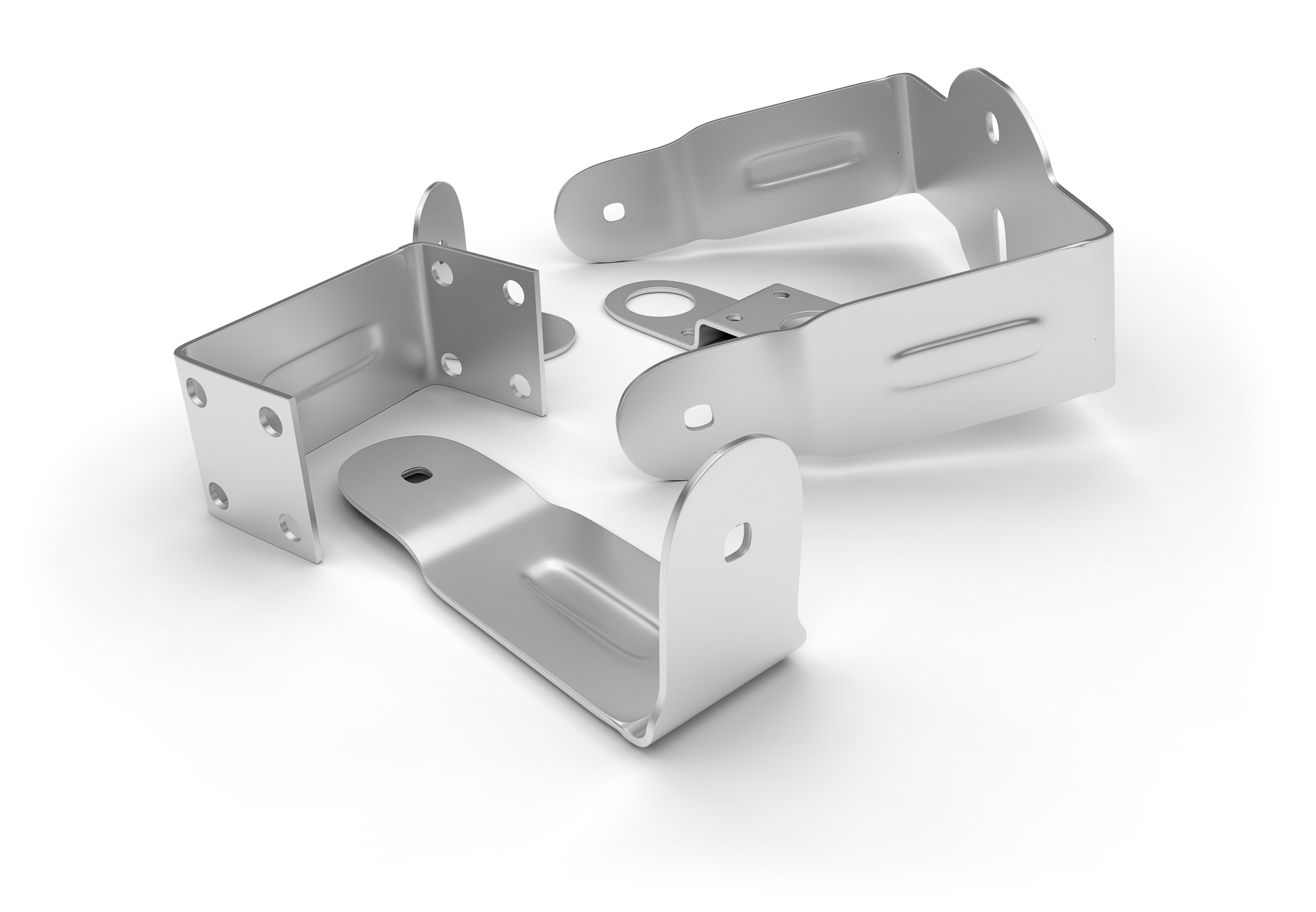

Metal accessories – bent, pressed, cold formed

We manufacture a wide range of metal accessories, depending on the needs, on CNC machines for wire processing and on progressive presses for sheet metal elements. Sheet metal accessories are manufactured on dedicated progressive tools or using a fibre laser. Punching and cutting often takes place in the same press cycle, which allows the highest performance of the manufactured elements to be achieved. For wire accessories, we manufacture complete parts entirely on CNC benders with multi-radial heads or on multi-slide machines for larger production volumes. Wire accessories with pressed parts are made by stamping on a machine that produces components from a wire coil. Thanks to custom-made tools, the wire workpieces can include such operations as bending, stamping, chamfering, drilling, tapping, swaging, and other forming operations, which are carried out during a single machining cycle on a machine with 16 CNC axes. Components are galvanized, chrome plated, or powder coated according to customer requirements.